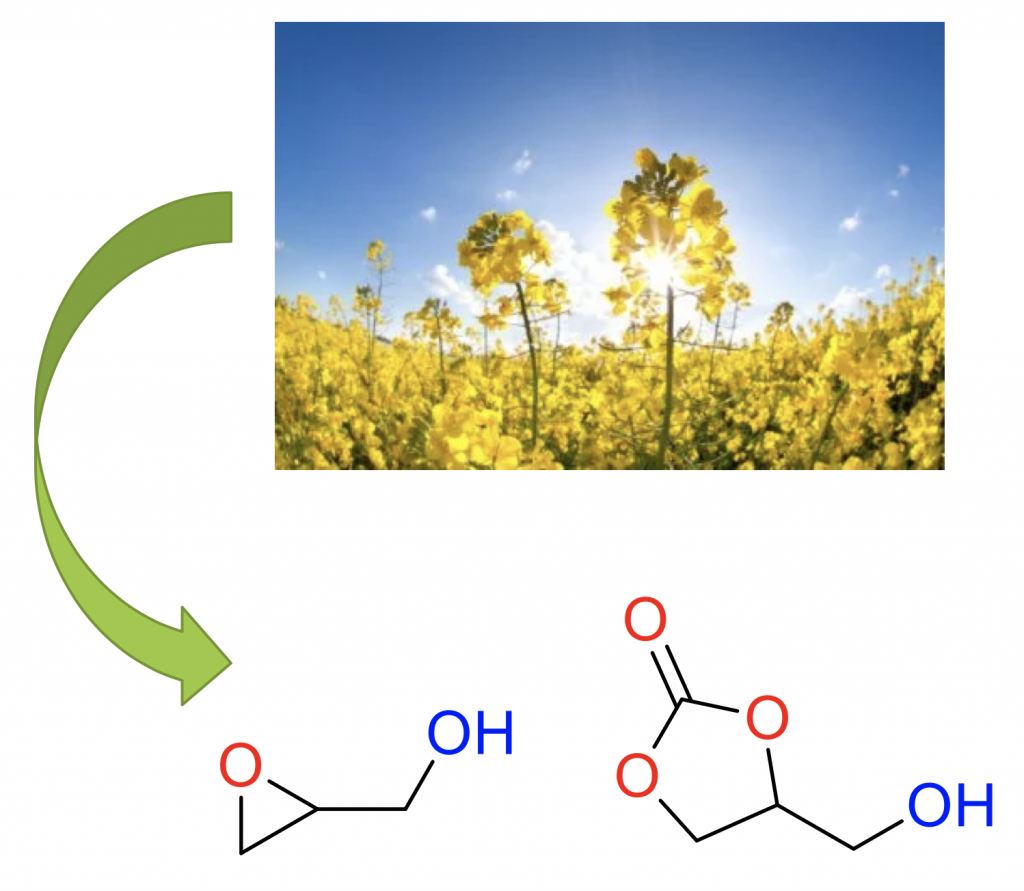

A New Sustainable, Chlorine-Free Epoxide Platform

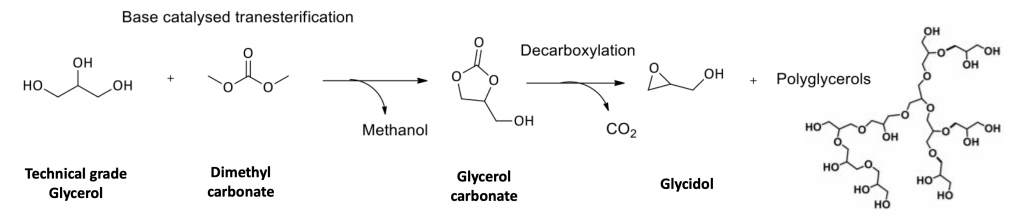

GLT have developed a green process for the conversion of glycerol, a waste byproduct from biodiesel production, into glycidol, a high value speciality epoxide which has the potential to change the current epoxide market. The technology involves a 2-step process whereby, glycerol and dimethyl carbonate are first converted to glycerol carbonate, which is then thermally converted to glycidol. GLT have demonstrated this technology at our demonstration plant at the Wilton centre and is ready for commercial deployment.

Business opportunity

GLT’s Green Glycidol technology offers end users a green, sustainable, safer alternative to the current petrochemically derived epoxide platforms. Current trends in the epoxide market make GLT’s technology highly attractive.

MARKET DISRUPTING GREEN EPOXIDE TECHNOLOGY

Market disrupting costs of production competitive with current methods and epoxide platforms

Growing market for green epoxy derivatives

GLOBAL PUSH FOR SUSTAINABILITY

Pull from consumer for products that are an alternative to the petrochemical equivalent

Green Glycidol has a large number of applications due to its dual functionality

INDUSTRY TREND FOR GREEN EPOXIDES

Chemical companies wish to reduce dependence on petrochemically based epoxides such as ethylene oxide and epichlorhydrin

Green Glycidol technology uses green, sustainable feedstock’s

SAFER EPOXIDES

The largest epoxide platform is a gasous hazardous chemical making it difficult and expensive to ship

Green Glycidol technology makes epoxide production and handling safer

CHLORINE FREE EPOXIDES

Chlorine free epoxides are highly attractive to end users

Green Glycidol technology is Chloride-free

WASTE VALORISATION

A bi-product of the biodiesel process, Glycerol production has seen rapid growth over the past 5 years with a resulting 90% price drop.

Green Glycidol technology converts this waste into a valuable resource

Green Glycidol Technology

GLT’s route valorises the biodiesel byproduct and reacts it with our low cost DMC production to produce glycerol carbonate and methanol. Methanol is recycled for use in biodiesel and DMC production whilst the glycerol carbonate is subsequently converted to glycidol and some polyglycerols. CO2 produced is subsequently recycled via DMC production technology making this integrated process highly sustainable and environmentally friendly.

Technology journey

The green glycidol has undergone over 4 years of development through lab R&D, lap pilot optimisation and demonstration at our demonstration plant facility at the Wilton centre. The technology is now ready for commercial deployment with detailed engineering designs beginning Q3 2019.

• Technology has undergone nearly 4 years of development through lab work, lab pilot demonstration and now semi commercial demonstration at our facility at Wilton

• Independent Technical-Economic evaluation of process carried out

• Green, sustainable feedstock’s

• Large group of local potential off takers developed

• Process delivers cost advantages disrupting the current epoxide market